We are going to easily build a flat collector solar collector box.

Although it is important to do it well, and take good care of the insulation, it is not the most important component of the entire system.

If the water circulation is good and circulates when it should, and the tank accumulates and conserves energy well, the collector, however regular it may be, will be well used.

To make our homemade collector, we need to know that it consists of the following parts:

The box must be slightly larger than the solar collector, if necessary.

It is logical to make the box first and then the custom collector.

But if you have already made the collector, you must make the custom box so that the collector is inside, and its terminals come out of the box. Or they can be extended to come out of it.

I am not going to go into detail about how to assemble a box, because this is not a DIY website.

It is very simple, it is as if we wanted to assemble a shallow closet without doors.

My box is made of pine wood, and I will varnish it with a special boat varnish (it provides a 10-year coverage guarantee)

The depth will be just right to introduce the insulating material and the copper collector inside.

And we can cover the bottom of the box with another piece of wood, or simply with 1 or several sheets of wood of the kind used in closets.

What we are looking for by covering the back part is nothing more than to prevent the insulating material from being directly exposed to the elements (sun and humidity).

I have used fairly large internal brackets, so that the box is solid.

If you use internal brackets, you have to consider their position, so that they do not occupy the place where the collector bars need to come out.

You can use anything that is not particularly flammable.

Among the things you can put in, cardboard is quite viable.

Cardboard is not anti-flammable, but it holds up very well to heat, it will not catch fire if there is no fire inside.

A specific material is not essential, if we do not have good quality materials we can make the box deeper to accommodate a thicker insulating material.

So, if we cannot put quality, we will put quantity, to achieve the same thing in the end :-p

I have put as a first layer, a bit of expanded polystyrene, the typical white cork.

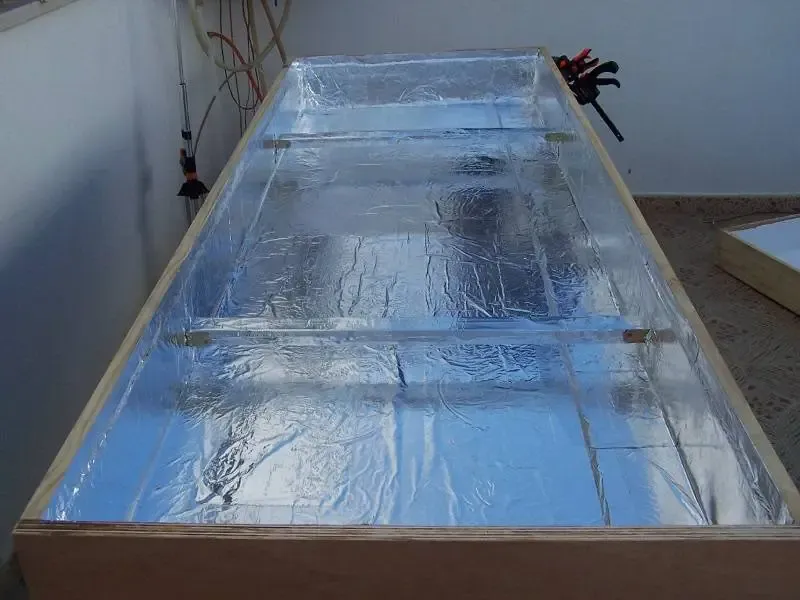

If you look at the photo, I first put some small brackets that will be the support for the collector.

The polystyrene is 4mm, and I have glued it with white carpenter's glue.

And it looks like this:

On top of the polystyrene, I have put several layers of aluminum foil glued with the same white glue as before.

Although aluminum is a conductor of temperature, here it serves as a shield, and it will not conduct the temperature inwards because it is in contact with the insulation.

You can put it or not, everyone can do it at their own discretion.

Here I have the box lying down, and I have already put the support for the collector.

The support is 2 crossbars of wood.

No need for brute force, some sticks with some small brackets. (I already put the brackets in before)

And here I finish with the interior insulation.

Polyurethane foam, be careful with the foam, it swells more than it seems.

Put little by little lumps, wait a few minutes and continue filling.

In the end we will have a collection of lumps and mountains. We will cut everything that sticks out to leave a nice cushion.

Keep in mind that if the space is very large and deep, we will use much more foam.

I used more foam than expected, should have made the box shallower.

I'm not going to stop now to explain what the absorber is for.

We build it and continue.

We can make it out of sheet metal, aluminum, anything that traps and conducts the temperature well.

I didn't have access to almost anything, and I built it with a sheet of cardboard, and lined it with aluminum foil.

Note that the absorber covers the support I made for the collector.

It doesn't matter, because both the collector and the absorber will be fixed to that support.

Of course, it is better to make some marks with a pencil or marker, so that when you go to screw things together we know where the bars are.

And this will look like this.

Installing the collector in the box

The collector, which is my , made up of welded bars, or a spiral hose, whatever, will be fixed to the absorber.

This way The collector is now assembled, all that's left is a bit of paint and the screen.

The collector bars, through which the water passes, and the absorber need to be in very, very close contact.

Do you remember when we're in bed in the winter, and we put our feet in those velvet-lined rubber bags filled with hot water, and you press against the bag to feel the heat more closely? Well, that's it.

If those bags were made of aluminum instead of velvet-lined rubber, we wouldn't even be able to put our feet on them.

A lot depends on this contact and its materials, so that the heat is felt quickly and strongly in the copper tubes, and the performance of the solar collector box is very efficient.

Just because it's homemade doesn't mean we don't do it right.

A good trick to make the tubes (whether copper or not) and the absorber (preferably this one if it has to be metallic) hug each other well and quickly transmit the temperature, is this.

Do you see how the subject goes?

A picture is worth a thousand words.

These grips, typical for holding the tubes on the wall, are screwed to the wooden bars that we put before.

And the aluminum makes an «ohm» shape to gain more contact with the tube.

INCORRECT way to join the copper tube with the absorber

CORRECT way to join the copper tube with the absorber

I have read that the industry usually welds the tubes with the absorber, even with cutting-edge technology to make said welds with ultrasound.

Puff!!! I'll stick with the homemade technology hahahahahahaha

No mysteries.

Matte black paint, call it ash color or whatever you want, but no glossy paint.

Preferably

https://comunidad.leroymerlin.es/t5/Bricopedia-Reparaci%C3%B3n-y/Qu%C3%A9-es-la-pintura-antical%C3%B

Heat-resistant paint is a special paint to withstand high temperatures.

If it is spray paint, it will be easier to apply.

As shown in the following photo, this is how everything is finally painted (only a small finish is missing on the contour)

You can also see in the same photo, the outlet of the collector to the outside.

The copper tube outlet at the top has a "T" to fit a Water pump for home solar heater inside.

The copper tube outlet at the bottom has nothing, just its threaded connector.

It is very important to make a small hole in the bottom of each box

In each of the boxes, always.

This is to avoid excess pressure that could damage the box or the acrylic or glass screen

The greenhouse effect is one thing, and it is another thing to be completely airtight.

Very hot air and water will come out through this hole

The water will be condensation product , and we don't want it to stay inside fogging up our screens

On each internal side of the box, we place 1 thin strip nailed with nails.

These 4 strips will be the support and settlement to place and seal the screen, which will finally close our box.

Optionally we can "dress" these strips with some insulation, which at the same time cushions the settlement of the screen.

The transparent screen or cover that will allow solar radiation to enter, and at the same time prevent heat from escaping (greenhouse effect), can be made of glass or acrylic.

I have preferred to use alveolar polycarbonate, for 4 reasons:

All that's left is to seal it with silicone and make an outer frame with aluminum adhesive.

Well, testing... a pre-heater with the box open and no water circulating...

The fact that it reaches almost 100 degrees in a very short time is already a good indication.

If we are going to install the collectors on a flat surface, we do not need a structure as complex and expensive as aluminum

I have built a homemade support based on PVC pipes.

Playing with unions based on "Tees" and elbows, we will assemble a solid structure.

We will have to consider securing it to the ground in some way , and the plates will also have to be fastened to the structure in some way.

It is important to make several holes in the PVC pipes in the place where rainwater cannot get in.

The reason for making these holes is to allow air to come in and out freely, so that the hot air inside does not deform the structure.